Home

O INNER é um instituto de DESENVOLVIMENTO HUMANO que se propõe a treinar MULTIPLICADORES e PRATICANTES de PNL, COACHING, HIPNOSE e outras práticas funcionais de desenvolvimento humano que podem ser utilizadas por profissionais de saúde, gestores, líderes, treinadores e demais pessoas interessadas em se tornarem AGENTES DE MUDANÇA em seu meio

PRÓXIMAS FORMAÇÕES PRESENCIAIS

Cursos e Certificados Registrados com Validade Nacional e Internacional

Aprenda técnicas assertivas e seguras para potencializar seu desempenho pessoal e profissional

*FORMAÇÃO TRAINER 360*

BRASÍLIA/DF

11 a 17 de Novembro

11 a 17 de Novembro

Segunda à Quinta: 18h às 22h

Sexta à Domingo: 10h às 20h.

Segunda à Quinta: 18h às 22h

Sexta à Domingo: 10h às 20h. *PNL MASTER PRACTITIONER*

em Brasília/DF

Módulo 1: 29 a 01 de Novembro (sexta, sábado e domingo)

Módulo 1: 29 a 01 de Novembro (sexta, sábado e domingo)

Módulo 2: 6 a 8 de Novembro /2024 (sexta, sábado e domingo)

Módulo 2: 6 a 8 de Novembro /2024 (sexta, sábado e domingo)

Sextas de 18h às 22h.

Sábados e Domingos de 10h as 20h.

Sextas de 18h às 22h.

Sábados e Domingos de 10h as 20h.

Presencial em Brasília/DF

Presencial em Brasília/DF

IMERSÃO PNL MÁXIMA 360

IMERSÃO PNL MÁXIMA 360

*FORMAÇÃO EXECUTIVA EM PNL PRACTITIONER INTERNACIONAL*

Brasília/DF

Módulo 1: 14 a 16 de Fevereiro/2025 (sexta, sábado e domingo)

Módulo 1: 14 a 16 de Fevereiro/2025 (sexta, sábado e domingo)

Módulo 2: 21 a 23 de Fevereiro/2025 (sexta, sábado e domingo)

Módulo 2: 21 a 23 de Fevereiro/2025 (sexta, sábado e domingo)

Sextas de 14h às 20h.

Sábados e Domingos de 10h as 20h.

Sextas de 14h às 20h.

Sábados e Domingos de 10h as 20h.

Presencial em Brasília/DF

Presencial em Brasília/DF

IMERSÃO PNL MÁXIMA 360

IMERSÃO PNL MÁXIMA 360

*FORMAÇÃO EXECUTIVA EM PNL PRACTITIONER INTERNACIONAL*

Brasília/DF

Módulo 1: 16 a 18 de Maio/2025 (sexta, sábado e domingo)

Módulo 1: 16 a 18 de Maio/2025 (sexta, sábado e domingo)

Módulo 2: 23 a 25 de Maio/2025 (sexta, sábado e domingo)

Módulo 2: 23 a 25 de Maio/2025 (sexta, sábado e domingo)

Sextas de 14h às 20h.

Sábados e Domingos de 10h as 20h.

Sextas de 14h às 20h.

Sábados e Domingos de 10h as 20h.

Presencial em Brasília/DF

Presencial em Brasília/DF

IMERSÃO PNL MÁXIMA 360

Conheça nossa Plataforma EAD com nossos diversos Cursos Online

Cursos Gratuítos

Cursos Online

Curso de Extensão em Fundamentos da Psicanálise 360

- 60 horas

12x R$ 29,83

ou R$ 297,00 à vista

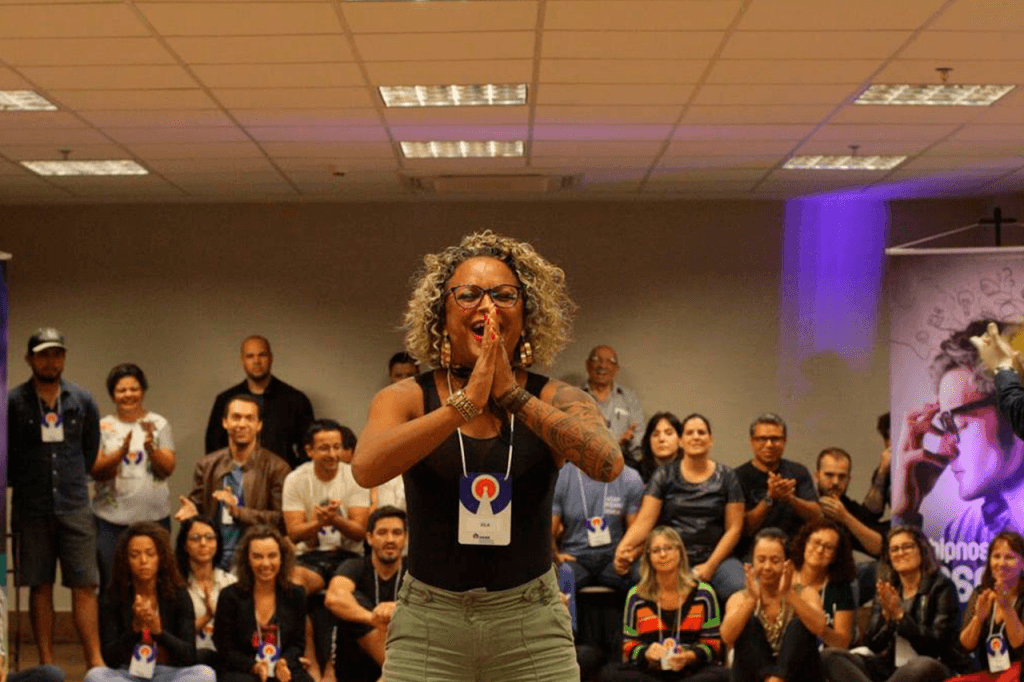

Faça como MILHARES de pessoas já fizeram

Confira o que dizem os nossos alunos

Mais de 200 TURMAS REALIZADAS e MILHARES de alunos FORMADOS.

AGENTE DE MUDANÇA é um profissional capacitado em processos de desenvolvimento humano com foco em mudanças comportamentais e educação mental, e tem como principal competência a de INFLUENCIAR eticamente e positivamente as pessoas a alcançarem seus objetivos e MULTIPLICAR o conhecimento adquirido no seu meio.

Ministrado por Eduardo Rocha

Eduardo Rocha conta com mais de 20 anos de experiência e, portanto, expertise ímpar na interação com o público por meio de aplicações didáticas, lúdicas e artísticas adaptadas aos treinamentos.

Ministrou dezenas de cursos de Hipnose Prática, Clínica e Conversacional, com centenas de alunos formados na última década.

Hoje atua como Coach Executivo, Hipnoterapeuta, Palestrante, Reprogramador Mental e tem sua carreira profissional reconhecida nacionalmente. Realizou mais de 500 palestras corporativas e workshop em empresas públicas e privadas de médio e grande porte em todo Brasil.

Trainer Internacional Licenciado pela The Society of NLP TM

Master Trainer em Hipnose

Master Coach Certificado

Mentor Executivo

Engenheiro Civil (Universidade Federal da Paraíba)

Administrador de Empresas (Universidade de Administração de Brasília)

Acadêmico de Psicologia (Universidade Católica)

Consultor Educacional

Hipnoterapeuta Licenciado

Palestrante Corporativo

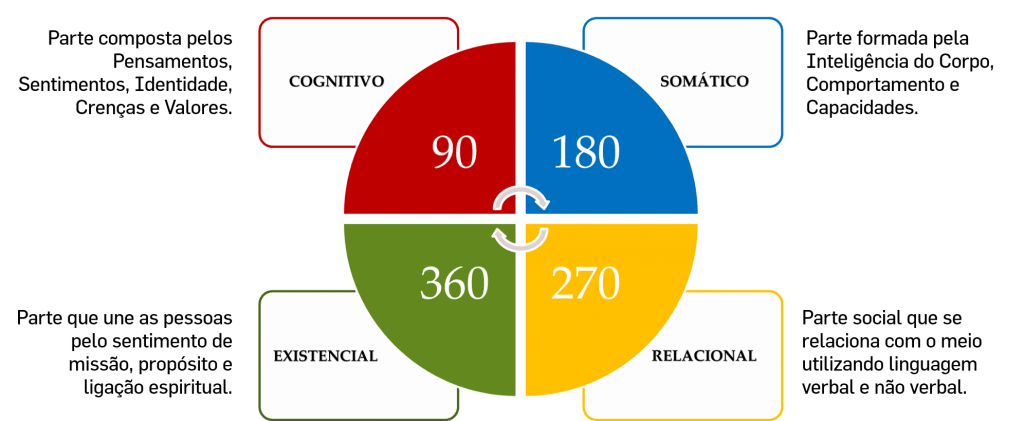

METODOLOGIA 360®

INTEGRATIVO + SISTÊMICO + ESTRATÉGICO

Inner na Mídia

Marcas & Negócios Correio Braziliense

O INNER foi destaque na Coluna Marcas & Negócios do Correio Braziliense

Empresários de Sucesso

O INNER foi destaque no Programa Empresário de Sucesso na Band New

Certificado Internacional

O INNER é uma Empresa Internacional, é isso mesmo e com Sede em outro país consegue emitir, apostilar e homologar o seu Certificado de forma Internacional.

ASSOCIAÇÃO BRASILEIRA DOS TERAPEUTAS HOLÍSTICOS

Alguns dos nossos clientes

A INNER LIGA PARA VOCÊ

Deixe seu contato que iremos entrar em contato com você.

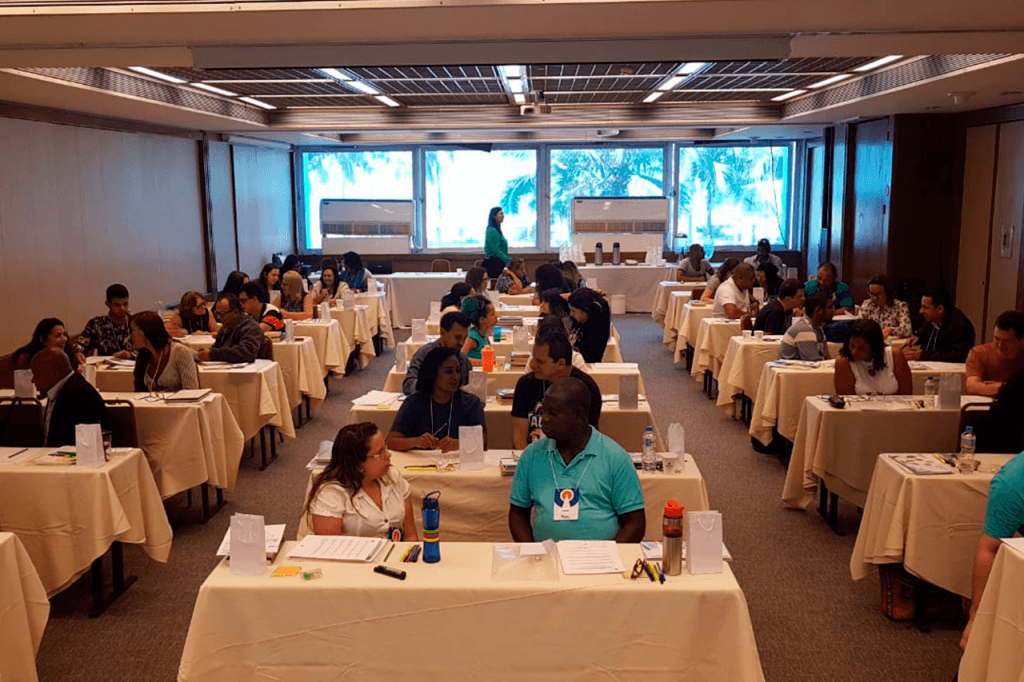

ESPAÇO INNER

O INNER é um instituto com SEDE em Brasília/DF e registrado nos principais orgãos reguladores, associações de referencia nacional e internacional. Possui infra-estrutura própria de cursos e mantem parceria com Hoteis e Centro de Convenções com estrutura confortável, segura e ampla para a realização de atividades durante os treinamentos. Além dos cursos, o INNER possui uma SALA VIP específica para realização de práticas supervisionadas após os treinamentos, exclusiva para os ALUNOS e MEMBROS.